India's material handling industry is undergoing a significant transformation, fueled by the adoption of cutting-edge technology. Among these advancements, Raschel bag making machines are emerging as a game-changer, optimizing production efficiency and product performance.

These advanced machines leverage intricate weaving patterns to create a wide spectrum bags, encompassing grocery bags, shopping bags, and niche applications. The versatility of Raschel machines allows manufacturers to respond to evolving market requirements, producing bags in various sizes, shapes, and materials to suit diverse customer preferences.

The integration of Raschel bag making machines offers a range of perks for Indian producers. Firstly, these machines improve production rate, enabling manufacturers to satisfy growing market demands.

Secondly, Raschel bags are known for their robustness, which reduces the risk of breakage during handling and transportation. Furthermore, these machines allow for precise control over bag specifications, enabling manufacturers to produce bags that differentiate themselves in a competitive market.

The expanding popularity of Raschel bag making machines in India is a clear indication to the importance they bring to the packaging sector. As the need for sustainable and efficient packaging solutions continues to climb, Raschel bag making machines are poised to play an even greater role in shaping the future of India's packaging industry.

This Textile Industry Embraces Raschel Technology for Sustainable Bags

India's textile sector is witnessing a shift towards sustainable practices, with a growing emphasis on eco-friendly materials and manufacturing methods. A key driver of this transformation is the adoption of advanced technologies like Raschel knitting machines. These innovative machines allow manufacturers to create durable and versatile bags from recycled materials, reducing reliance on virgin resources and minimizing environmental impact.

Raschel technology offers a spectrum of benefits for sustainable bag production. It enables the creation of intricate patterns with high-quality finish, catering to diverse consumer demands. Moreover, Raschel machines are known for their productivity, allowing manufacturers to produce bags at a faster rate while minimizing waste generation.

The growing popularity of sustainable bags is fueled by increasing customer awareness about the environmental impact of conventional products. Consumers are actively seeking alternatives that are both stylish and eco-conscious, creating a need for sustainable bag options in the market. Indian textile manufacturers are meeting to this demand by leveraging Raschel technology to produce high-quality bags from recycled materials, establishing themselves as leaders in the sustainable fashion sector.

Threads to Trends: The Rise of Raschel Bag Manufacturing in India

The Indian scene is buzzing with the energy of Raschel bag manufacturing. This heritage weaving technique, renowned for its complex designs and durable fabric, has undergone a stunning transformation in recent years. Raschel bags, once mostly confined to niche markets, are now adorning the shelves of both local and global retailers.

- Fueled by a growing demand for green fashion, Raschel bag manufacturers are utilizing innovative methods to create stylish and responsible bags.

- Showcasing vibrant floral patterns to sleek contemporary designs, Raschel bags offer a diverse range of styles to suit to every taste and occasion.

Furthermore, the rise of e-commerce has created new avenues for Raschel bag manufacturers to expand their customer base. With online platforms, these entrepreneurs are showcasing their unique creations with a global audience.

Innovations in Raschel Bag Production: Shaping India's Future

Raschel bags have always occupied a prominent place in the Indian market, known for their durability and versatility. Recently, remarkable innovations in Raschel bag production are emerging, poised to alter the industry and shape India's future.

From advanced manufacturing techniques to green materials, these advancements are propelling the boundaries of what's possible in Raschel bag design and production.

A key driver behind this transformation is the growing request for sustainable and green products. Manufacturers are now embracing innovative resources like recycled plastic and organic cotton to produce Raschel bags that are both stylish and environmentally sound.

Furthermore, innovation is playing a essential role in streamlining production processes. Automated equipment are boosting efficiency while lowering waste and overhead.

These innovations not only benefit the environment but also produce new possibilities for growth and development in India's economy. By embracing these advancements, Raschel bag producers are securing themselves at the forefront of a dynamic industry and contributing to a more sustainable future.

Unveiling the Potential of Raschel Bag Making Machines in India

The Indian manufacturing sector has seen a surge in demand for innovative and sustainable bag-making solutions. Raschel bag making machines, known for their flexibility, are emerging as a key component in this evolving landscape. These state-of-the-art machines offer manufacturers the capability to produce durable bags in a wide range of designs and materials, catering to diverse consumer needs.

From sturdy shopping bags to elegant promotional items, Raschel bag making machines facilitate unparalleled control in fabric weaving. This leads in bags that are not only visually appealing but also incredibly strong. Moreover, the output of these machines allows manufacturers to satisfy market demands effectively while minimizing production costs.

Furthermore, Raschel bag making machines are known for their eco-friendly features. Many models utilize recycled materials and employ energy-saving technologies, making check here them a responsible choice for environmentally aware businesses.

- Adopting Raschel bag making machines presents a significant benefit for Indian manufacturers to enhance their production capabilities and tap into new market segments.

- The growing demand for sustainable packaging solutions further bolsters the case for embracing these innovative machines.

A Comprehensive Guide to Raschel Bag Making Machines in India

India's manufacturing sector is experiencing a surge in demand for durable and stylish bags. This has led to a rise in the popularity of Raschel bag making machines, known for their ability to produce high-quality bags with intricate designs. Businesses looking to enter this growing market should consider investing in these sophisticated machines.

- Essential characteristics of Raschel bag making machines include their ability to handle a wide range of fabrics, create complex patterns, and offer high production capacity.

- Mastering the different types of Raschel machines available in India is crucial for choosing the right equipment. Some common types include flat-bed, circular knitting, and tri-cot machines, each with its own advantages.

- Choosing a reputable machine supplier is essential to ensure reliability. Researching different brands and comparing their offerings can help you find the best fit for your needs.

Furthermore, training programs are available to help operators understand the intricacies of Raschel bag making machines. Investing in these programs can enhance productivity and maximize output.

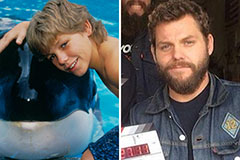

Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Melissa Joan Hart Then & Now!

Melissa Joan Hart Then & Now! Michelle Trachtenberg Then & Now!

Michelle Trachtenberg Then & Now! Tina Majorino Then & Now!

Tina Majorino Then & Now! Samantha Fox Then & Now!

Samantha Fox Then & Now!